Alternative Data as a Competitive Advantage

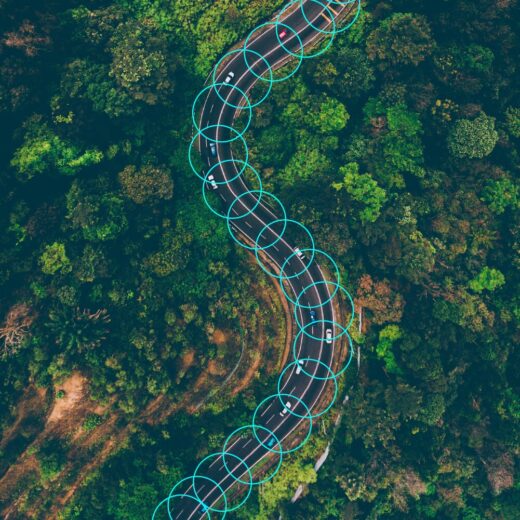

Chemical Producer

Problem

- Need to better understand the market landscape and changing customer demands

- Build up competitive intelligence

Solution

- Use distributed and highly parallelizable Cloud infrastructure crawl and gather data about competitive products on the market. The collected data are use to:

– Track competitor portfolios

– Collect signals about new entrants on the market

– Better understand customer sentiment

Impact

- More focused product development and relevant product launches based on real time market signals

AI Sales Forecasting

Major Swiss Chemical company

Developing a state-of-the-art forecasting approach by combining multiple forecasting models to achieve a 97-98% accuracy, leading to monetary and time savings

Problem

- The customer was looking to automate the sales forecasting process which to date was performed in a manual way, making it cumbersome and error prone

Solution

- New approach to improve forecasting quality and the effort needed to maintain it using new data sources like Forward looking indicators, Financial metrics: (GDP, Inflation, FX rates) and Big events (e.g. new years in china, olympic games etc.)

Impact

- Automation -> less manual work, less errors, less time

- Higher accuracy (97-98%)

- Better planning/cost savings

AI Automated Forecasting

Swiss Chemical Company

Developing a state-of-the-art forecasting approach by combining multiple forecasting models to achieve a 97-98% accuracy, leading to monetary and time savings

Challenge

- Needed to accurately forecast sales, raw materials supply and market demand for finished goods

- Existing forecasting methods were labour-intensive and inconsistent

- Models failing to provide accurate, reliable forecasts

Solution

- Created powerful new methods to generate and combine forecasting models

- Developed modern, state-of-the-art forecasting algorithm

- Delivered an automated solution which aggregated data sources and combined forecasting models together to attain higher accuracy

Business Impact

- Reached 97-98% in forecasting accuracy through combination of forecasting model, higher than any single model on its own

- Enabled an optimisation of operations, resulting in monetary and time savings

- Decreased risk of manual errors through forecasting automation

AI Formula Multi-criterion Optimisation

Swiss Chemical Company

Developing a Deep Learning model to optimise existing formulas resulting in

a better consumer test score for AI optimised formulas compared to the originals

Challenge

- Development of new formulas relies heavily on feedback from consumer tests to evaluate market fit

- Goal is to reduce costs of new formula development by making use of AI and reducing the need for consumer testing

- Plan to achieve that by predicting the main characteristics of a formula and what changes to make to it

Solution

- Unit8 created a new algorithm based on cutting edge AI technique to optimise existing formulas on multiple criteria to increase market fit

- The developed deep learning algorithm feeds into a web application also developed for this purpose which recommends specific changes to be made to a formula to improve market fit

Business Impact

- Products which use the our AI-optimised recommendations outperformed the original formulas in market fit during a subsequent consumer test

(Re-)formulation of Flavour Formulas

Swiss Chemical Company

Developing an algorithm to determine optimal formula composition alternatives to reduce costs by up to 50% while keeping a similar molecular quality

Challenge

- Varying price and availability of ingredients over time due to supply chain issue, for example

- These issues put pressure on profit margin and order fulfillment

- Previously, finding cost-efficient and ingredients with decent availability was done manually and automation attempts had failed to bring tangible results

Solution

- Completely changed to optimisation algorithm from previous failed attempts

- Our approach tries to find a new set of ingredients which keeps the same molecules as originally but at a lower cost

- Possible to tune the results based on a cost vs. result spectrum

- Built a user-friendly frontend to deploy the solution in self-service

Business impact

- Frontend makes it incredibly easy for flavourers to compare optimised formulas with the originals and save results

- Algorithm finds better solutions with an optimal trade-off between cost and molecular quality

- Reduction of cost by up to 50%

- Unit8 algorithm runs in seconds instead of hours for previous algos

Domain Specific Search Engine (PowerSearch)

Swiss Chemical Company

Establishing a search engine to aggregate and facilitate access to product data for R&D activities, resulting in faster search times and decreased research costs

Challenge

- Client manages a large product portfolio based on 1000s of patents with product info spread over various systems

- Product managers unable to fully harness the available data for new product development

- Previous search tool has several downfalls

Solution

- Set up a user-friendly search engine covering all company data in collaboration with internal team

- Integrated ML models previously developed for the same client into this new PowerSearch tool

Business impact

- Significant decrease in time spent looking for information

- Information that was previously inaccessible is now available to end users

- Improved R&D efficiency and reduced research costs

- As of Dec 2020, used in 25 countries with 250 unique users/week

Logistic Base Optimisation

Swiss Chemical Company

Creating custom statistical algorithm to define optimal “logistic bases” for formulas in order to minimize the amount of pouring and reduce costs

Challenge

- Ingredients need to be mixed at certain ratios to create flavours. Some ingredients are pre-mixed into what is called “logistic bases” to reduce the number of pours

- Choice of logistic bases by human expert is becoming harder

- Goal to find optimal logistic bases through an algorithm to increase pouring efficiency

Solution

- Created custom statistical algorithm that incorporates information about the creation process and historical production data

- Solution was however not implemented because deemed too risk to change the whole production process

Business impact

- Theoretically, the new logistic bases created through our algorithm would reduce the number of pours by 10%

- Would lead to a cost reduction after break-even with initial production process change investment

Extraction of Formula’s Bases

Swiss Chemical Company

Creating and training a deep-learning model to simplify existing formulas, resulting in 30% reduction in number of ingredients while keeping end formulas identical in 99% of cases

Challenge

- Chemical formulas contain too many ingredients

- Makes it more complex to understand the formula composition and leads to higher cost and longer manufacturing process

- Goal to find algorithmic way to simplify existing formulas by creating a portfolio of “bases” that could be combined and reused to create formulas

Solution

- Trained a highly specialised deep-learning model able to learn and detect efficient combinations of ingredients to use to form those reusable “bases”

- Model defined bases according to user defined metrics

Business impact

- Number of ingredients needed to attain same final result reduced by 30%

- End formula is the same in 99% of cases

- Significant saving potential for manufacturing and logistics

- Bases discovered can become building blocks to help creative process

Production Line Optimisation

Swiss Chemical Company

Analysing a production line to improve production speed and anticipate slow-downs resulting in 15% speed-up with a 8x ROI

Challenge

- Perfume production plant efficiency was very variable and production encountered several slow-downs

Solution

- Conducted initial data analysis and discovered that slow-downs were caused by some valves being clogged

- Cleaning the valves lead to overall equipment effectiveness (OEE) improvements

- Built custom application to monitor KPIs in real time and alert operators about undetected issues

Business impact

- Increased production line efficiency and speed

- OEE increased by 8%, speed-up of production by 15%

- 8x return on investment

Cloud Web Scraping

Swiss Chemical Company

Creating automated web scraping tool to augment data assets with external web data in near real-time leading to best-in-class data analysis and AI models

Challenge

- Client’s data assets contained, amongst other, external web data obtained on competitor’s websites

- Needed to figure out a better way to gather new data and managed existing data assets

- Goal to automate the collection and scraping process of new data

Solution

- Combined cloud services, public libraries and proxy servers to create a tool that continuously crawls relevant web resources automatically

- The tool crawls resources, retrieves key data, and structures those data to facilitate analysis

Business impact

- Information is always up-to-date thanks to automatic crawling

- Replaces unnecessary manual work and reduces potential for errors

- Best-in-class data assets to maximise quality of analysis and AI models

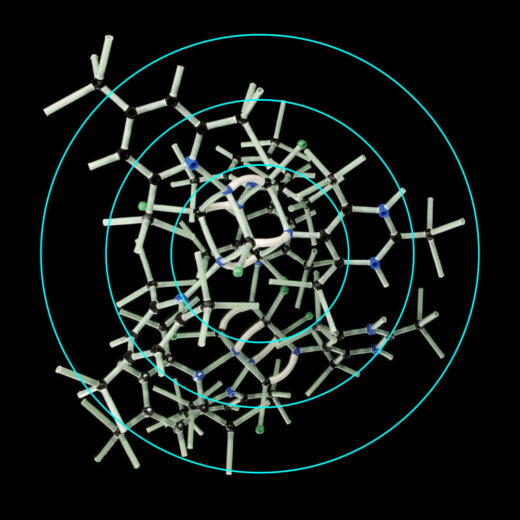

Prediction of Product Properties

Swiss Chemical Company

Training a deep neural network to predict end product properties without having to actually mix ingredients together, reducing development cost and time

Challenge

- R&D activities to create new product by combining different ingredients produce waste and take time

- Difficult to predict end product properties and taste without actually combining ingredients and observing the result

- Goal to predict final properties through algorithm instead of physically

Solution

- Trained neural networks to analyse chemical interactions and product properties data

- Solution predicts end properties, suggest totally new formulas, and recommends potential improvements to existing formulas

- Models designed to be natively compatible with current systems used by client, leading to easier integration

Business impact

- Development time and cost of new products and formulas significantly reduced

- Lower waste of ingredients

- Creators can predict product properties even before creating the first samples

- Reached beyond customer requirements by integrating this model into a search engine created for the same client

Centralised Models API

Swiss Chemical Company

Creating an API platform to facilitate access to insights from various models from different systems, laying the foundation for more ML use across the company

Challenge

- Variety of chemical, physical and sometimes ML models scattered across the entire company

- Models thus quickly became outdated and couldn’t be properly maintained

- Different production sites operating in silos instead of profiting from collaboration

Solution

- Created API platform to facilitate model access, storage and maintenance

- Integrated API into Azure ML to allow timely model retraining

- Built web app linked to API and used to test models with users before integrating them into other company applications

Business impact

- API platform has become the official company-wide platform to derive insights from models

- 20 models available, integrated into 5 applications

- Infrastructure is now accessible from anywhere in the world by employees

- Laying the foundation for more ML uses by employees adopting a more and more data-driven approach to problems

Smart Blending

Swiss Chemical Company

Optimising combination of different ingredient batches to maximise molecular composition consistency of products overtime

Challenge

- Ingredients have changing molecular compositions depending on season, supplier and other factors

- Need to blend together different batches to keep molecular composition consistent over time

- Desire to monitor changes in quality and alert business to allow quick response if needed

Solution

- Optimisation problem with trade-off between quantity produced and molecular composition precision

- Implemented frontend with 6-step optimisation process to attain highest possible molecular composition consistency

Business impact

- All steps for composition optimisation neatly packaged into same user-friendly frontend

- Savings from rolling stock and lead time reduction of approx. CHF 400k per annum

State-of-the-art ML Model Assessment

Swiss Chemical Company

Conducting a ML model assessment and delivering a comprehensive report confirming the direction taken by the internal team and foresting innovation

Challenge

- Client needed help to assess internally-developed ML models to determine if they were worth patenting

- Unclear goal on what to do with existing models and lacking MLOps best-practices with poor reproducibility

Solution

- Wrote codebase on Azure ML with MLOps practices allowing reproducibility and fast iterations and benchmarked model against well-known datasets

- Delivered comprehensive report (official ICLR publication) analysing why the method worked, proposing improvement, conducting a literature review

and providing future guidelines

Business impact

- Results were encouraging for the internal team

- Fostered innovative spirit and the method gained traction within the company

- Report was a new asset that could be used as a stepping stone for a paper publication

Process Order Optimisation in Manufacturing Line

Swiss Chemical Company

Defining an mathematically optimal manufacturing sequence order to reduce total production time of perfumes

Challenge

- Manufacturing line produces perfumes by blending ingredients

- Sequence order can be optimised to reduce time and complexity of production

- Goal to compute optimal scheduling to pour ingredients for each blend

- Past factory data was scarce and implementation initially seemed complicated

Solution

- Implemented mathematical optimisation algorithm that defined optimal production sequence to manufacture perfumes

- Simulation to test impact of different optimisation methods compared to what happens in the factory

- Chose “Iterated Greedy” method

Business impact

- Faster manufacturing due to mathematically optimal production sequence

- Approx. 3% improvement in manufacturing speed

- Resulting in 6 digits cost saving figures

Future of Perfumery

Swiss Chemical Company

Developing multi-modal tool to enable transformation of image or text description into an fully-fledged perfume

Challenge

- Complexity of developing tool with very little labelled data and to handle the fuzzy nature of of matching images and text to perfumes

Solution

- Used pre-trained transformer models to understand text and images

- Produced semantic joint embedding to link text and images to perfume descriptors

- Generative models either created a new perfume or suggested a matching one from existing range

Business impact

- Tool was a POC and achieved its aim of showing the feasibility of such an approach

- Showed to the C-level management and founders of company which praised the tool

- Stepping stone for potential future project building on this initial POC

AI Supply Chain Forecasting

Major Swiss Chemical company

Problem

- The need to improve the current forecasting process (raw-materials, finished goods and sales)

Solution

- New approach to improve forecasting quality and the effort needed to maintain it using new data sources like Forward looking indicators, Financial metrics: (GDP, Inflation, FX rates) and Big events (e.g. new years in china, olympic games etc.)

Impact

- Automation -> less manual work, less errors, less time

- Higher accuracy (97-98%)

- Better planning/cost savings

Building domain specific search engine

International chemical producer

Establishing a search engine to aggregate and facilitate access to product data for R&D activities, resulting in faster search times and decreased research costs

Problem

- Limited search abilities of very large product catalogue, no employee has a global view of this catalogue

Solution

- Build up of a user-friendly search engine, which allows for seamlessly going through the formulas’ database and quickly identifying components that are needed

Impact

- Ability to quickly search through the past data and apply the learnings to the new offerings

- Time saving and productivity increase

Optimal re-formulation

Major Swiss flavour and fragrance company

Problem

- Raw material shortages

- Cost fluctuations & impact on profit margins

- Difficulties in finding the best combinations of raw materials

Solution

- Optimization algorithm and platform

- Reformulation on molecular level

- Ability to reduce/replace certain combinations of ingredients while preserving overall properties of the product

Impact

- Significant cost savings possible due to ingredient optimizations

- Some reformulations have been successfully accepted and sold

- Immune to shortages/less impact of ingredient price fluctuations

Predicting and optimising products properties

Major Swiss chemical producer

Implemented deep learning models able to predict the main characteristics and traits of finished products, along with potential market fit

Problem

- Predict main characteristics and traits of finished products, along with potential market fit

Solution

- Deep learning on several data sources

- The resulting predictive models have been integrated into the tool used by creators. Now they know the parameters of the end product even before they create the first samples of the product.

- Our models can also make specific recommendations to improve products

Impact

- Increase odds of market success of the products

- Shortening the production cycles and reducing costs